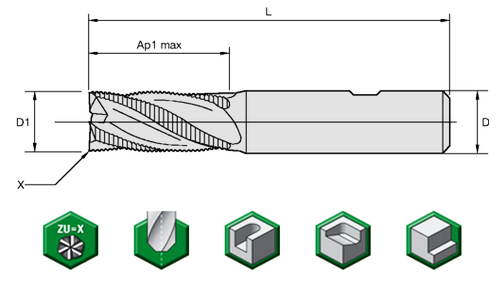

roughing end mill diagram

These make the cutting process faster than with a regular end mill. These lower the shock load during the cutter rotation both enabling a.

End Mill An Overview Sciencedirect Topics

Roughing End Mills - Cobalt and High Speed Steel.

. The spiral flute end mill compared to a straight flute does a similar function. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. This reduces chatter and vibration which could otherwise be larger because of the jagged teeth.

Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. Corner Rounding End Mills. Multiple teeth come into contact with the workpiece at the same time.

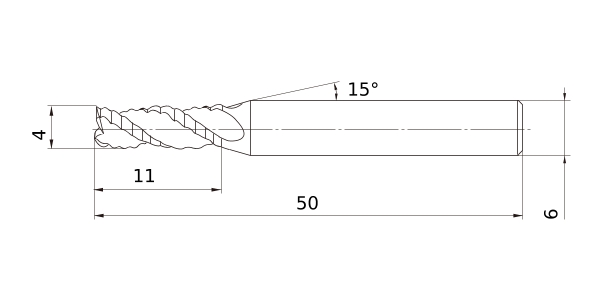

Download scientific diagram Dimensions of the roughing mill components and side guide. More on this Product Distributors Order Online. Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone.

They are sometimes referred to as Corn Cob cutters or Hog Mills - so called after the pig who grinds away or consumes anything in its path. The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

Read customer reviews find best sellers. This is illustrated in the. Specializing in High-Performance End Mills From Modular End Mills to Solid Carbide More.

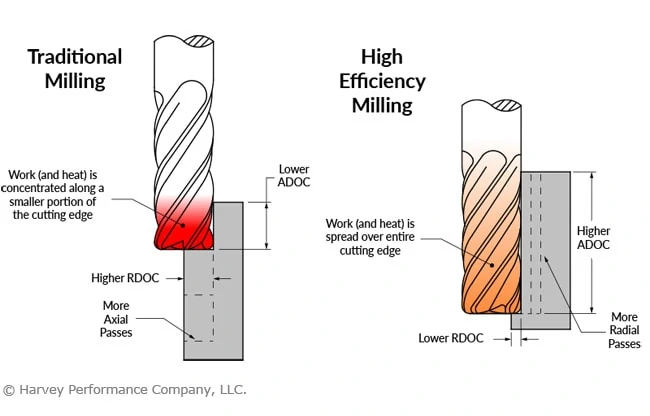

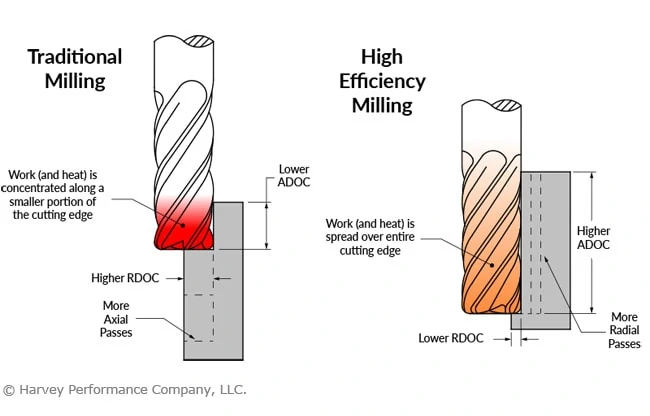

The Mechanism of Position-Mode Side Guide in. The tooth design allows for little to no vibration but leaves. A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation.

Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required. Drill A tool for drilling. Great for large surface area work roughing end mills have numerous serrations teeth in the flutes to quickly remove large amounts of material leaving a rough finish.

Roughing End Mills also known as ripping cutters or hoggers are designed to remove large amounts of metal quickly and more efficiently than standard end mills. Standards Roughers Long Lengths Inch Metric HS Carbide. View Profile View Forum Posts Titanium Join Date Feb 2014 Location FL Posts 3472 Post Thanks Like Likes Given 11844 Likes Received 4002.

Choosing an end mill is no simple task. A Cobalt coarse pitch rougher for high stock removal in difficult to machine materials. Large temperature variations occur at the surface region of the work-roll owing to severe temperature.

Ad Precision End Mills for Your Machine Cutting Needs With Custom Diameter Length More. Center holes at both ends enables a user to resharpen the end mill by grinding the face of the flute without distorting the roughing form. Originally Posted by ChipSplitter.

Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. Side milling curved surface milling and drilling are possible only by one. The roughing end mill has jagged teeth.

06-12-2020 0902 AM 61. Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. Ad For Taps Dies Cutting and Measuring Tools.

It is measured from the start of the necked portion to the bottom of the cutting end of the tool. Normally a 20 reduction in effective horsepower is used. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

Coarse Pitch Non-Center Cutting Roughing Cobalt End Mills. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. The tooth design allows for little to no vibration but leaves a rougher finish.

18 Roughing End Mill. Tooling Materials Expensive high quality materials yield more durable tools that. Figure 11 shows surface temperature variation of the work-rolls in the roughing mill where they are cooled using two water sprays with convection heat transfer coefficient of 30 000 W m 2 K 1 and heat transfer coefficient for the film cooling region is taken as 6000 W m 2 K 1.

Steel Roughing rolling mill stand is an important part of a work stand roll bearing chock and roller adjustment device is installed on the frame. Roughing end mill This kind of end mill utilizes a wavy tooth form cut on the periphery. Coarse tooth roughing end mills remove large chips for heavy cuts deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing application.

Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. End mill A multi-functional tool which has cutting edges on the periphery and an end face. The steel roughing rolling mill stands are used to reduce the thickness of the steel while at the same time extending the overall length.

They are designed to remove large amounts of material quickly and more efficiently than standard end mills. The cut bits of metal are smaller than usual and therefore easier to clear. Every business must consider which end mill best fits the desired application and results in minimum production costs.

These wavy teeth form many successive cutting edges producing many small chips resulting in a relatively rough surface finish but the swarf takes the form of short thin sections and is more manageable than a thicker more riboon-like section. Corner chamfer end mills have an angled cutting edge and are used. This results in lower cutting pressures at a given radial depth of cut.

Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Ad Browse discover thousands of brands. Carbide Square End Mills.

The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep-pocket milling applications. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Cutting edges are only on a top.

Roughing End Mills रफ ग ए ड म ल In Midc Bhosari Pune Orient Tools Id 3666888530

The Secret Mechanics Of High Feed End Mills In The Loupe

Schematic Diagram Of The Side Milling Process Download Scientific Diagram

Mitsubishi Materials Web Catalogue Products Information Solid End Mills Cmra Cmrad0400

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

8 Ways You Re Killing Your End Mill In The Loupe

Atc Rough Cutting End Mill 218 2 Indexable Milling Insert Holder Indexable Milling Insert Holder Milling Bar Shenzhen Ussharp Cutting Technology Co Ltd

End Mill An Overview Sciencedirect Topics

5 Cutter Workpiece Engagement Geometry Extraction For Ball End Mill Download Scientific Diagram

Roughing Chip Breaker Bits 4 Flute F4zc45 End Mills Drills Frezycnc Eu

Basic End Mills Technical Information Msc Industrial Supply Co

4 Flute End Mills For Hardened Steel End Mills Drills Frezycnc Eu

M A Ford Tuffcut Xr Al 3 Flute Roughing End Mill For Aluminum 3 8x1x2 1 2x 020r Gem Weldon M A Ford

Roughing End Mill Kyocera Unimerco

End Mills Cad Cam Engineering Worldwide

Geometrical Parameters Of An Endmill Download Scientific Diagram